NEWS

Industry News

Freudenberg Sealing Technologies Automated Turning Technology Boosting Efficiency

Time:17 Aug,2016

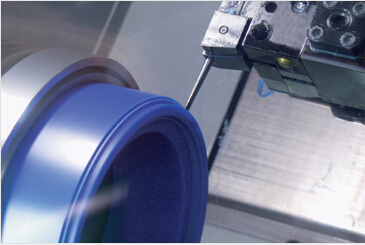

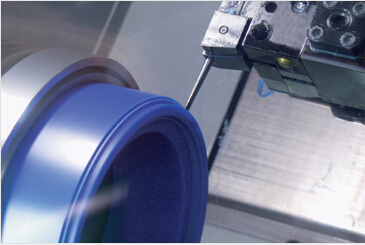

At its facility in Bromma near Stockholm, the Swedish capital, Freudenberg Xpress has invested in advanced, automated tool technology, making its small series manufacturing even more efficient and economical – to the customer’s benefit.

Freudenberg Xpress

Turned seals from Freudenberg Xpress are the first choice for small production runs. It would take several weeks to produce a tool for a classic injection molding process. A costly approach, it would not pay off for small volumes. The material attributes of turned seals from Freudenberg Xpress are comparable to those of conventionally produced series parts.

Bromma is already the third Freudenberg Xpress location where this highly advanced automated technology is proving itself. An integrated bar feeder system conveys the seal material to the CNC machine fully automatically. Manual activities are eliminated.

Freudenberg Xpress

Turned seals from Freudenberg Xpress are the first choice for small production runs. It would take several weeks to produce a tool for a classic injection molding process. A costly approach, it would not pay off for small volumes. The material attributes of turned seals from Freudenberg Xpress are comparable to those of conventionally produced series parts.

Bromma is already the third Freudenberg Xpress location where this highly advanced automated technology is proving itself. An integrated bar feeder system conveys the seal material to the CNC machine fully automatically. Manual activities are eliminated.

Freudenberg Xpress

Turned seals from Freudenberg Xpress are the first choice for small production runs. It would take several weeks to produce a tool for a classic injection molding process. A costly approach, it would not pay off for small volumes. The material attributes of turned seals from Freudenberg Xpress are comparable to those of conventionally produced series parts.

Bromma is already the third Freudenberg Xpress location where this highly advanced automated technology is proving itself. An integrated bar feeder system conveys the seal material to the CNC machine fully automatically. Manual activities are eliminated.

Freudenberg Xpress

Turned seals from Freudenberg Xpress are the first choice for small production runs. It would take several weeks to produce a tool for a classic injection molding process. A costly approach, it would not pay off for small volumes. The material attributes of turned seals from Freudenberg Xpress are comparable to those of conventionally produced series parts.

Bromma is already the third Freudenberg Xpress location where this highly advanced automated technology is proving itself. An integrated bar feeder system conveys the seal material to the CNC machine fully automatically. Manual activities are eliminated.

MANAGER Wang

MANAGER Wang +86-159 6666 2619

+86-159 6666 2619 1-1514,building2,No.15612,century avenue,hightech zone,jinan,shandong,china.

1-1514,building2,No.15612,century avenue,hightech zone,jinan,shandong,china. MANAGER Wang

MANAGER Wang +86-159 6666 2619

+86-159 6666 2619 +86-531-88684258

+86-531-88684258 +86-531-88684258

+86-531-88684258 admin@vgb-bearing.com

admin@vgb-bearing.com 1-1514,building2,No.15612,century avenue

1-1514,building2,No.15612,century avenue